Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

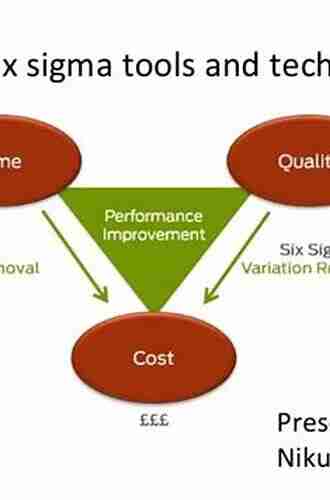

12 Lean Six Sigma Tools And Techniques To Reduce The Cost Of Quality From The

Quality is of utmost importance in any business. It directly impacts customer satisfaction, overall productivity, and ultimately, . In today's competitive world, organizations need to consistently improve their processes to deliver high-quality products or services at the lowest cost possible. This is where Lean Six Sigma comes into play.

What is Lean Six Sigma?

Lean Six Sigma is a powerful methodology that focuses on reducing waste, improving efficiency, and maximizing customer value. It combines two well-known improvement philosophies, Lean and Six Sigma, to eliminate defects and enhance process performance. By implementing Lean Six Sigma principles, organizations can not only minimize variations but also optimize their operations for continuous improvement.

The Cost of Quality

The cost of quality refers to the expenses incurred by an organization due to producing defective products or services. These costs include prevention, appraisal, internal failure, and external failure costs. By implementing Lean Six Sigma tools and techniques, organizations can minimize these costs and enhance their competitive advantage in the market.

4.1 out of 5

| Language | : | English |

| File size | : | 6738 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 177 pages |

| Paperback | : | 336 pages |

| Item Weight | : | 14.1 ounces |

| Dimensions | : | 5.51 x 0.87 x 8.07 inches |

| X-Ray for textbooks | : | Enabled |

12 Lean Six Sigma Tools and Techniques

1. Value Stream Mapping (VSM): VSM is a visual tool that allows organizations to identify and eliminate non-value-added activities in their processes. By mapping the current state and designing the future state, organizations can optimize their operations and reduce wastage.

2. Kaizen Events: Kaizen Events are short-term improvement activities that bring together cross-functional teams to solve specific problems. These events are highly focused and aim to achieve significant process improvements in a short period.

3. 5S Methodology: 5S focuses on workplace organization and standardization. By implementing Sort, Set in Order, Shine, Standardize, and Sustain, organizations can create a clean and efficient workspace, reducing waste and improving productivity.

4. DMAIC Methodology: DMAIC stands for Define, Measure, Analyze, Improve, and Control. It is a structured problem-solving approach used to identify and eliminate the root causes of process issues, improving overall performance.

5. Poka-Yoke: Poka-Yoke, also known as mistake-proofing, aims to prevent errors from occurring or to identify them at an early stage. By implementing simple yet effective mechanisms, organizations can minimize defects and their associated costs.

6. Kanban System: The Kanban system is a visual scheduling tool that helps organizations manage their inventory levels effectively. It provides real-time information about demand and supply, enabling just-in-time production and minimizing excess inventory.

7. Root Cause Analysis (RCA): RCA is a problem-solving technique that aims to identify the underlying causes of issues or defects. By understanding and addressing the root causes, organizations can prevent similar problems from recurring in the future.

8. Statistical Process Control (SPC): SPC involves the use of statistical tools to monitor and control process variations. By analyzing data in real-time, organizations can identify deviations and take timely corrective actions to maintain process stability and reduce defects.

9. Failure Mode and Effects Analysis (FMEA): FMEA is a proactive risk assessment tool used to identify potential failure modes and their impacts on processes. By prioritizing and addressing high-risk areas, organizations can prevent failures and improve overall quality.

10. Standard Work: Standard work involves documenting and following the best-known method for performing a particular task. By standardizing processes, organizations can reduce variations, increase efficiency, and minimize defects.

11. Visual Management: Visual management uses visual cues and tools to communicate information, instructions, and performance metrics to employees. By making information easily accessible, organizations can enhance transparency, teamwork, and decision-making.

12. Total Productive Maintenance (TPM): TPM aims to achieve zero breakdowns, zero defects, and zero accidents. By implementing proactive maintenance practices and involving all employees, organizations can improve equipment reliability, reduce downtime, and ultimately, enhance product quality.

Lean Six Sigma provides a systematic approach to improve the quality of products and services while reducing costs. By implementing the 12 aforementioned tools and techniques, organizations can streamline their processes, minimize defects, and enhance customer satisfaction. The continuous pursuit of operational excellence through Lean Six Sigma can result in significant cost savings and a sustainable competitive advantage.

4.1 out of 5

| Language | : | English |

| File size | : | 6738 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Print length | : | 177 pages |

| Paperback | : | 336 pages |

| Item Weight | : | 14.1 ounces |

| Dimensions | : | 5.51 x 0.87 x 8.07 inches |

| X-Ray for textbooks | : | Enabled |

The BASICS Handbook is designed to show personnel at all levels within a manufacturing operations environment that, with easy to understand continuous improvement tools, they can make a difference to operational performance where safety, quality, cost, delivery, and people are paramount to business success. The tools and techniques throughout, based upon examples from the author’s experience, demonstrate that no matter what industry, they can bring the desired added value.

This book will help any manufacturing shop floor add value in terms of quality/cost and delivery performance. It will also show how using tools and techniques from the “coal face” out will improve process performance by using simple data collection and measurement – not only on outputs, but just as importantly on “critical to quality inputs” such as process parameters and their processing windows – to deliver the desired output KPIs. The power and confidence that this gives to local experts and processing teams enable them to make informed decisions, preventing drifts and non-conforming product: prevention being better than cure.

The result of these changes is a tangible cultural impact on the shop floor, raising the level at which operating teams work and improving morale. BASICS will enable staff at all levels to understand their performance measures and produce sustainable results. The book contains practical tools, methods, and techniques that have been tried and tested by the author over a successful 30-year career as a contractor transforming variable processing and inconsistent KPI results.

Allen Ginsberg

Allen GinsbergKathy Santo Dog Sense Kathy Santo - Unlocking the secrets...

Are you a dog lover who...

Raymond Parker

Raymond Parker10 Presidents Who Were Killed In Office - Shocking Truth...

Throughout history, the role of a president...

Isaac Asimov

Isaac AsimovUnveiling a World of Magic: Beautifully Illustrated...

Bedtime stories have always held a...

James Joyce

James JoyceThe Blind Parables: An Anthology Of Poems

For centuries, poetry has...

Clay Powell

Clay PowellRival Conceptions Of Freedom In Modern Iran

The Struggle for Freedom in...

Cristian Cox

Cristian CoxAdvances In Their Chemistry And Biological Aspects

In recent years,...

Dominic Simmons

Dominic SimmonsGetting Into Mini Reefs For The Marine Aquarium

Are you interested in enhancing the...

Vincent Mitchell

Vincent MitchellExploring the Intriguing Connection Between History,...

When one thinks of Chinese martial...

Christian Barnes

Christian BarnesMighty Meg And The Accidental Nemesis: Unleashing the...

In the world of superheroes, there are many...

Kirk Hayes

Kirk HayesA Journey through the World of Nhb Drama Classics: Full...

Welcome to a fascinating exploration of Nhb...

Gerald Bell

Gerald BellWeed Cross Stitch Pattern Rachel Worth - The Perfect...

Are you a stoner who loves a little...

Ernesto Sabato

Ernesto SabatoDiscover the Breathtaking Beauty of the South West Coast...

Are you ready for an...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Jeffery BellPleasant Garden Images Of America - Exploring the Picturesque Essence of a...

Jeffery BellPleasant Garden Images Of America - Exploring the Picturesque Essence of a...

Jace MitchellUnleash the Potential: Open New Window for a Seamless Web Browsing Experience

Jace MitchellUnleash the Potential: Open New Window for a Seamless Web Browsing Experience Josh CarterFollow ·18.8k

Josh CarterFollow ·18.8k Luke BlairFollow ·19.5k

Luke BlairFollow ·19.5k Mason PowellFollow ·19.6k

Mason PowellFollow ·19.6k Bob CooperFollow ·9.2k

Bob CooperFollow ·9.2k Francisco CoxFollow ·16.9k

Francisco CoxFollow ·16.9k Herb SimmonsFollow ·6.4k

Herb SimmonsFollow ·6.4k Dylan MitchellFollow ·18.9k

Dylan MitchellFollow ·18.9k Devin RossFollow ·13.6k

Devin RossFollow ·13.6k