Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

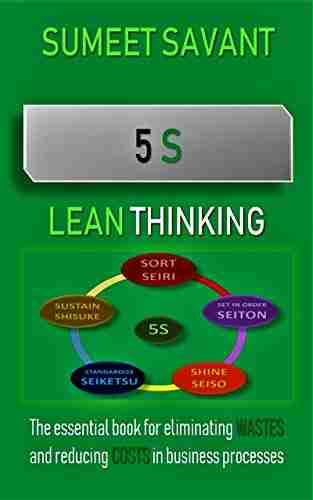

The Incredible Influence of 5s Lean Thinking: Sumeet Savant's Journey Towards Efficiency

In today's fast-paced and competitive world, businesses are constantly looking for ways to enhance efficiency, reduce waste, and improve productivity. One effective strategy that has gained significant prominence is 5s Lean Thinking. This article delves into the incredible influence of 5s Lean Thinking and explores the remarkable journey of Sumeet Savant, a trailblazer in implementing this methodology.

What is 5s Lean Thinking?

5s Lean Thinking is a management philosophy derived from the Toyota Production System, with the primary objective of eliminating waste and optimizing workplace efficiency. The term "5s" refers to five Japanese words starting with "s": Seiri (Sort),Seiton (Set in Order),Seiso (Shine),Seiketsu (Standardize),and Shitsuke (Sustain). These principles, when embraced and consistently practiced, enhance organization, cleanliness, and overall productivity.

The Story of Sumeet Savant

One person who has made significant strides in embracing and advocating 5s Lean Thinking is Sumeet Savant. Sumeet's journey towards efficiency started when he joined a manufacturing firm as a production manager. Faced with numerous challenges and bottlenecks, he sought ways to streamline operations and boost output. This quest led him to discover the power of 5s Lean Thinking.

4.2 out of 5

| Language | : | English |

| File size | : | 8653 KB |

| Text-to-Speech | : | Enabled |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Lending | : | Enabled |

| Screen Reader | : | Supported |

| Print length | : | 104 pages |

Discovery and Implementation

Sumeet realized that the traditional approach to production management was becoming obsolete and inefficient. He began studying various management philosophies and methodologies, ultimately stumbling upon 5s Lean Thinking. Recognizing its potential to revolutionize manufacturing processes, he made it his mission to implement this methodology across his organization.

The Impact of 5s Lean Thinking

As Sumeet introduced 5s Lean Thinking into the manufacturing process, he witnessed a remarkable transformation. Waste, in the form of excess inventory, overproduction, and unnecessary motion, was significantly reduced. Production cycles became streamlined, leading to improved quality, reduced lead times, and increased customer satisfaction.

Employee Engagement and Empowerment

One aspect that sets 5s Lean Thinking apart is its emphasis on employee involvement and empowerment. Sumeet understood the importance of engaging the workforce in the transformation process. By encouraging employees to take ownership of their workspaces, he fostered a culture of continuous improvement and efficiency.

Benefits of 5s Lean Thinking

Enhanced Efficiency and Productivity

The implementation of 5s Lean Thinking provides businesses with a systematic approach to maximize efficiency and productivity. By eliminating waste and streamlining processes, organizations can achieve higher outputs within existing resources and timeframes.

Improved Quality Control

5s Lean Thinking promotes standardized work processes. Implementing this methodology ensures that quality checks and controls are embedded in every step of the production process, resulting in improved product quality and customer satisfaction.

Cost Reduction

The reduction of waste and the optimization of resources lead to significant cost savings. 5s Lean Thinking helps businesses identify and eliminate unnecessary expenses, resulting in enhanced profitability and competitiveness.

Safe and Engaging Work Environment

Implementing 5s Lean Thinking creates a safer and more engaging work environment. By ensuring that everything has a designated place and is easily accessible, the risk of accidents or injuries is minimized. Additionally, an organized and clean workspace contributes to higher employee morale and satisfaction.

The Future of 5s Lean Thinking

As the business landscape continues to evolve rapidly, the relevance and importance of 5s Lean Thinking are only set to increase. With its focus on eliminating waste, continuous improvement, and employee engagement, this methodology provides organizations with a competitive edge.

Building on Success

Sumeet Savant's success in implementing 5s Lean Thinking has inspired others to follow suit. His journey has ignited a movement, with businesses across various sectors embracing this methodology. The lessons learned from Sumeet's experience serve as a guiding light for organizations looking to enhance efficiency and achieve sustainable growth.

New Frontiers: Applying 5s Lean Thinking Beyond Manufacturing

While 5s Lean Thinking originated in manufacturing, its principles and benefits extend far beyond this sector. Many businesses in service industries, healthcare, IT, and hospitality have successfully adopted and adapted 5s Lean Thinking to enhance their operations. This not only demonstrates the versatility of the methodology but also points to a future where 5s Lean Thinking becomes a mainstream management practice.

The remarkable journey of Sumeet Savant exemplifies the incredible influence of 5s Lean Thinking. By implementing this methodology, Sumeet has revolutionized production processes, driven efficiency, and empowered employees. The principles of 5s Lean Thinking offer unparalleled opportunities for businesses to enhance productivity, reduce waste, and ultimately achieve sustainable growth. As more organizations embrace this methodology, the future holds a promise of increased efficiency, competitiveness, and success.

4.2 out of 5

| Language | : | English |

| File size | : | 8653 KB |

| Text-to-Speech | : | Enabled |

| Enhanced typesetting | : | Enabled |

| Word Wise | : | Enabled |

| Lending | : | Enabled |

| Screen Reader | : | Supported |

| Print length | : | 104 pages |

Understanding 5S, knowing when to use 5S, and implementing end to end 5S methodology has never been easier!

Have you ever wanted to implement 5S in your company's workplace?

Have you ever wanted to implement 5S for your customer's workplace?

Have you ever wanted to identify wastes, achieve cost savings, cost reductions, and cost leadership in your company?

If the anwer to any of these questions is yes, you need look no further.

Lean Six Sigma Master Black Belt Mentor and Coach, Sumeet Savant, with more than a decade of experience in executing, leading, and mentoring hundreds of Lean Six Sigma improvement projects brings to you a simple, straight forward, no nonsense book which will enable you understand 5S, know when to use 5S, implement end to end 5S, and achieve the cost reductions you have always dreamt of, quickly, effectively, and efficiently.

He shares his belief: "Continuous Lean improvements are possible only when you know, appreciate, and implement 5S in your workplace"

Do Act Now and have a LOOK INSIDE the short book to have a brief experience of the immensely valuable information it has in store for you.

With this book, you will get to,

- Know what is 5S.

- Know, undestand, and appreciate the need for 5S.

- Know the different 'S' in the 5S.

- Know and understand Seiri in detail, with an effective Red Tagging implementation strategy.

- Know and understand Seiton in detail, with an effective Layout Optimization implementation strategy.

- Know and understand Seiso in detail, with an effective Cleaning Schedule implementation strategy.

- Know and understand Seiketsu in detail, with effective implementation strategies.

- Know and understand Shitsuke in detail, with effective implementation strategies.

- And know all these in the least number of words possible – to help you lean your processes and achieve cost reductions faster.

This may very well be the last book you will ever need to implement 5S methodology on your workplace and achieve overall cost effectiveness.

We are sure about it! And, so will you be!

Allen Ginsberg

Allen GinsbergKathy Santo Dog Sense Kathy Santo - Unlocking the secrets...

Are you a dog lover who...

Raymond Parker

Raymond Parker10 Presidents Who Were Killed In Office - Shocking Truth...

Throughout history, the role of a president...

Isaac Asimov

Isaac AsimovUnveiling a World of Magic: Beautifully Illustrated...

Bedtime stories have always held a...

James Joyce

James JoyceThe Blind Parables: An Anthology Of Poems

For centuries, poetry has...

Clay Powell

Clay PowellRival Conceptions Of Freedom In Modern Iran

The Struggle for Freedom in...

Cristian Cox

Cristian CoxAdvances In Their Chemistry And Biological Aspects

In recent years,...

Dominic Simmons

Dominic SimmonsGetting Into Mini Reefs For The Marine Aquarium

Are you interested in enhancing the...

Vincent Mitchell

Vincent MitchellExploring the Intriguing Connection Between History,...

When one thinks of Chinese martial...

Christian Barnes

Christian BarnesMighty Meg And The Accidental Nemesis: Unleashing the...

In the world of superheroes, there are many...

Kirk Hayes

Kirk HayesA Journey through the World of Nhb Drama Classics: Full...

Welcome to a fascinating exploration of Nhb...

Gerald Bell

Gerald BellWeed Cross Stitch Pattern Rachel Worth - The Perfect...

Are you a stoner who loves a little...

Ernesto Sabato

Ernesto SabatoDiscover the Breathtaking Beauty of the South West Coast...

Are you ready for an...

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Samuel Taylor ColeridgeThe Comprehensive Guide to Essential Topology: A Must-Have in the Springer...

Samuel Taylor ColeridgeThe Comprehensive Guide to Essential Topology: A Must-Have in the Springer...

Earl WilliamsThe Fascinating World of Medicinal Chemistry: Unleashing the Potential of...

Earl WilliamsThe Fascinating World of Medicinal Chemistry: Unleashing the Potential of...

Jan MitchellNew GCSE French Edexcel Revision Guide For The Grade Course - CGP GCSE French

Jan MitchellNew GCSE French Edexcel Revision Guide For The Grade Course - CGP GCSE French Emilio CoxFollow ·17.3k

Emilio CoxFollow ·17.3k Neil GaimanFollow ·11.4k

Neil GaimanFollow ·11.4k Patrick HayesFollow ·14.5k

Patrick HayesFollow ·14.5k Milan KunderaFollow ·19.4k

Milan KunderaFollow ·19.4k Paulo CoelhoFollow ·3.3k

Paulo CoelhoFollow ·3.3k Hector BlairFollow ·2.3k

Hector BlairFollow ·2.3k Shannon SimmonsFollow ·19.3k

Shannon SimmonsFollow ·19.3k Jake PowellFollow ·12.2k

Jake PowellFollow ·12.2k